The Cobra system is a so-called open system. The opposite of an open system is a closed system, such as a hydraulic-based system. Unlike a closed system, there is no constant pressure in an open system. This means there is no overpressure in the system, either when the hand lance is used or not.

The pressure builds up the moment the water trigger on the hand lance is held in. In a closed system, the pressure is constant from the moment the system is activated until it is switched off.

Pressure through resistance

In order for the water to reach workflow at the nozzle, a pressure needs to be built up. The pressure is built up through the resistance created at the transition from the hose to the pipe in the hand lance and finally through the nozzle. To create sufficient resistance to achieve the correct pressure and flow, the nozzle is designed in two diameters. The diameter depends on the power of the water pump.

The water pump delivers different amounts of water depending on its power: 33 kW generates 60 l/min, and a 17 kW water pump delivers 30 l/min.

Without the narrowing from the hose to the hand lance, the pressure at the nozzle is not as high. This can be demonstrated by disconnecting the hand lance from the hose and flushing water, then comparing it with the pressure achieved when the lance is connected to the hose.

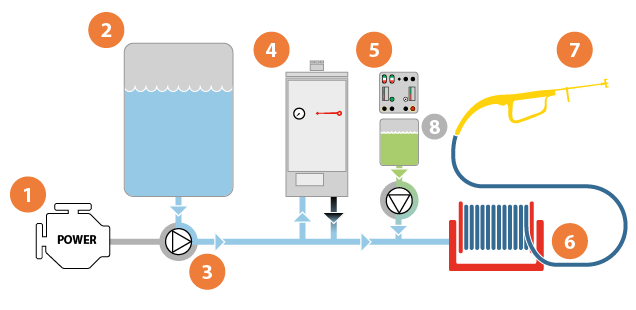

- Power source

- Water tank

- Water pump

- Abrasive vessel

- Control panel

- Hose and hose reel

- Hand lance

- Additive pump system (optional)

How the Cobra system works

Cobra is started and can be operated from the control panel (5). There is also an emergency stop button.

The power source drives the water pump, which is fed with water from a water tank.

The water is led to the abrasive tank, where 90% of the water is transferred directly to the hose and the hand lance. The remaining 10% of the water passes through the abrasive vessel to be mixed with the abrasive.

Abrasive is used to achieve the optimum cutting performance of the Cobra. When the abrasive trigger on the hand lance is pressed, a signal is sent to allow the abrasive to mix with the water jet. Resulting in approximately 4% abrasive mix at the nozzle.

Water pump

A typical configuration of the water pump on the Cobra unit is a high-pressure pump with a required power source of 33 kW or 17 kW. The first one generates about 60 l/min, and the second one about 30 l/min.

Both pumps have a working pressure of 300 bar.

The name of the unit indicates which pump and power source the system has:

For example, C 360 H stands for “Cobra 300 bar, 60 l/min, hydraulic”, while C 330 P stands for “Cobra 300 bar, 30 l/min, gasoline (petrol)”.

Abrasive vessel

The abrasive vessel is not a pressure vessel and contains no gas. It is filled with abrasive and water.

The 10% of the water that does not go directly from the water tank to the lance passes through the abrasive vessel. With the right flow rate, a vacuum is created in the abrasive vessel that sucks up the abrasive. With this technique, the abrasive vessel does not need to be pressurized to deliver the abrasive. When the vessel is empty of abrasive, it is filled with water.

Protective sleeve

A protective sleeve is attached to the hand lance. It is attached with Velcro and encloses the bayonet fitting that connects the hand lance and the high-pressure hose. The protective sleeve is uniquely designed and dimensioned to suit the purpose and to minimize the consequences of a possible hose rupture or other hose failures during operation. The protective sleeve is manufactured by TST Sweden, a global supplier of personal protection for high-pressure cleaning and water jetting up to 3000 bar / 43 500 psi.