Droplet size and spray pattern are essential when it comes to absorbing heat. It is the surface of the water droplet that absorbs and cools the heat radiation from the fire gases. Therefore, it is of great importance to get as large an effective surface area as possible. Many small droplets together create a larger total effective spray area per litre of water.

The droplet size from a spray nozzle varies depending on pressure and flow. A conventional system has low pressure and a high water flow, which generates a good throw length but larger droplets than can be achieved with high pressure and low water flow. Cobra uses a pressure of 300 bar and a flow rate of 60 l/min, which results in many small droplets in a fine water mist.

The high pressure, together with an abrasive, can penetrate virtually any material, it is just a matter of time. Once the material is penetrated, the high pressure and lower water flow result in a fine water mist with a throw length of up to 15 meters and a large effective surface area. The fire gases are cooled, resulting in reduced temperature in the fire compartment – making it a cleaner and safer environment to enter and extinguish the initial fire.

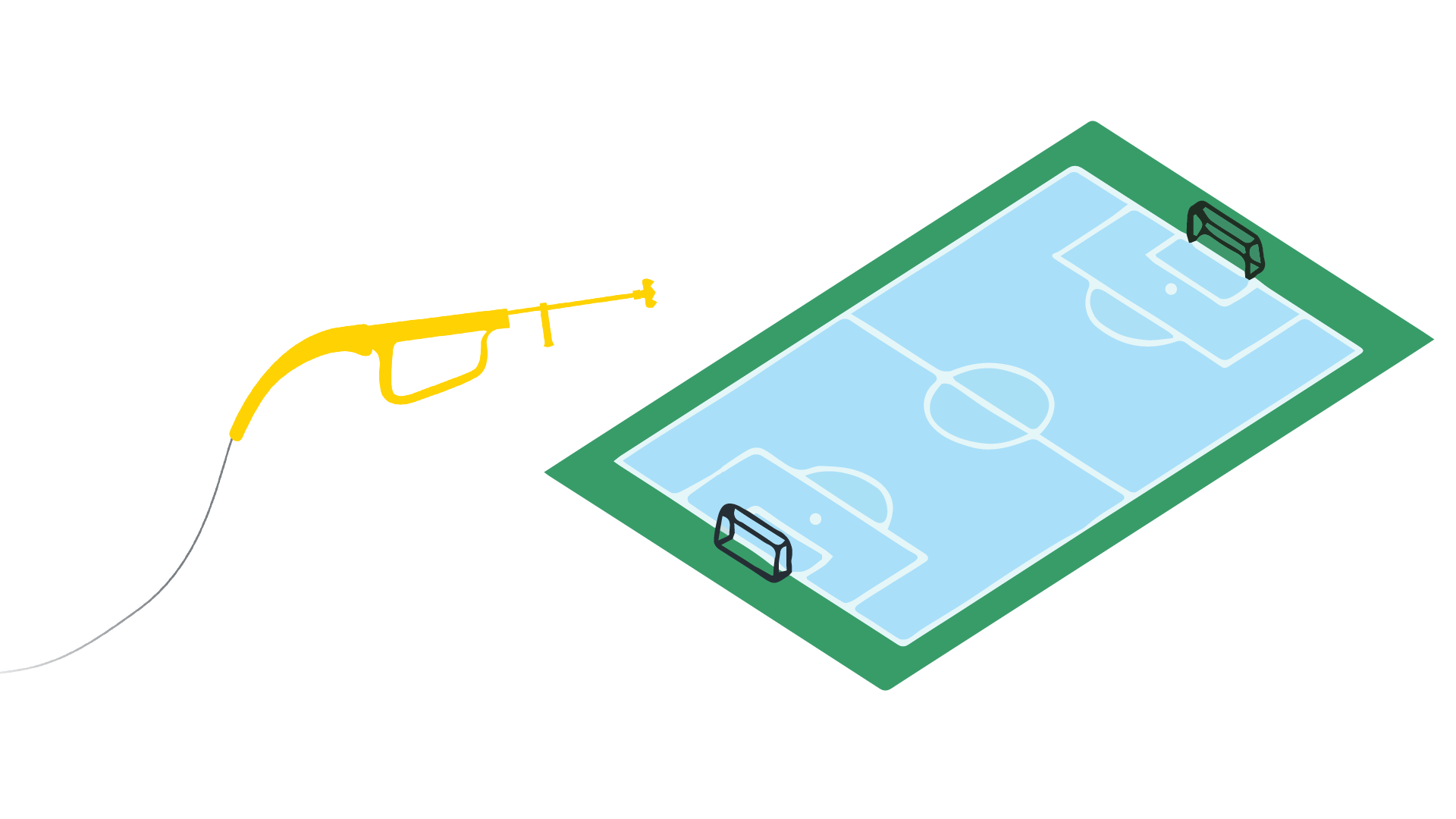

To describe this fact in a more understandable and tangible way, the metaphor of a football pitch can be used. In this example, the same given amount of water is used in all illustrations.

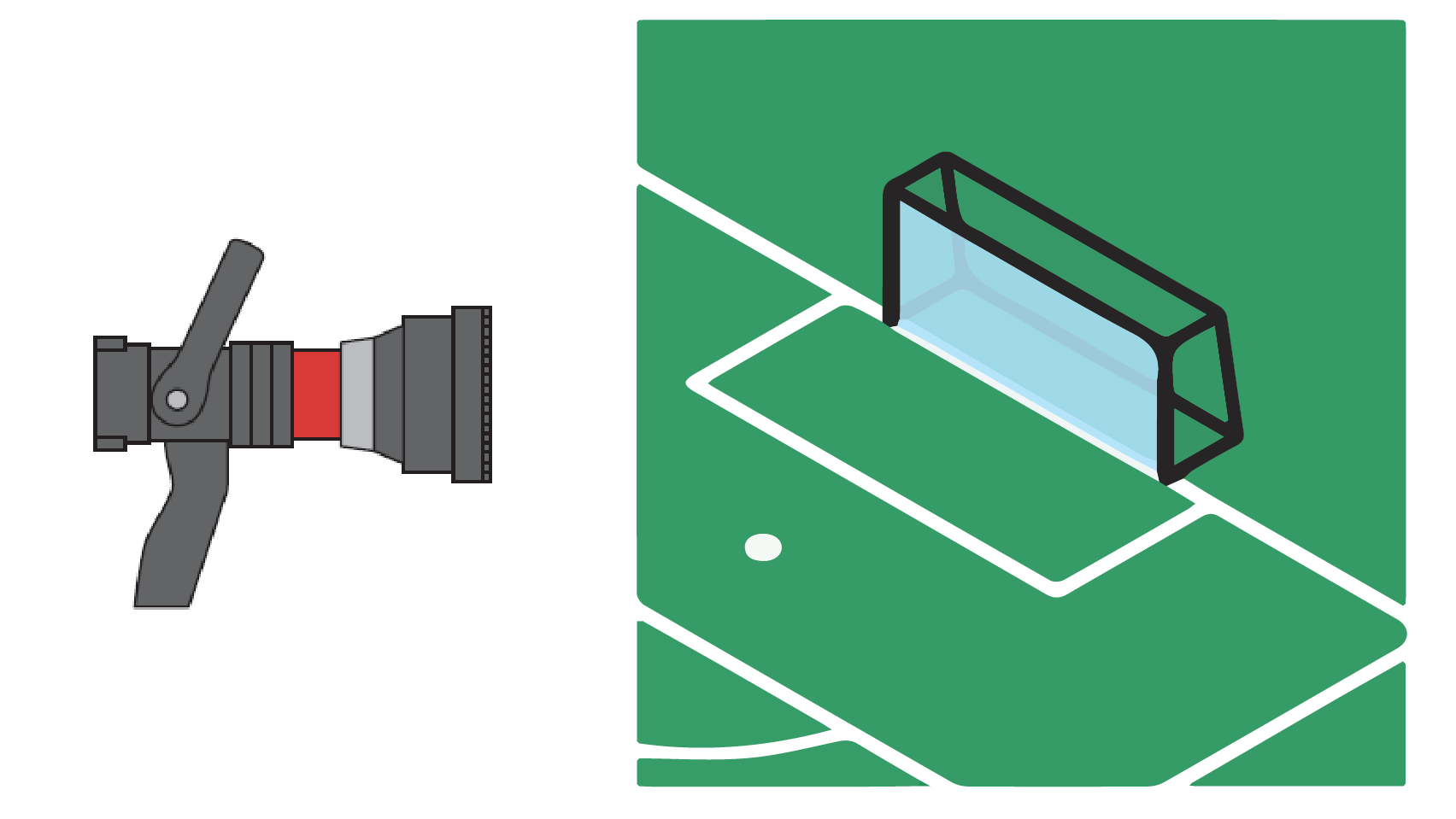

A given volume of water introduced at 8 bar will cover half a football goal.

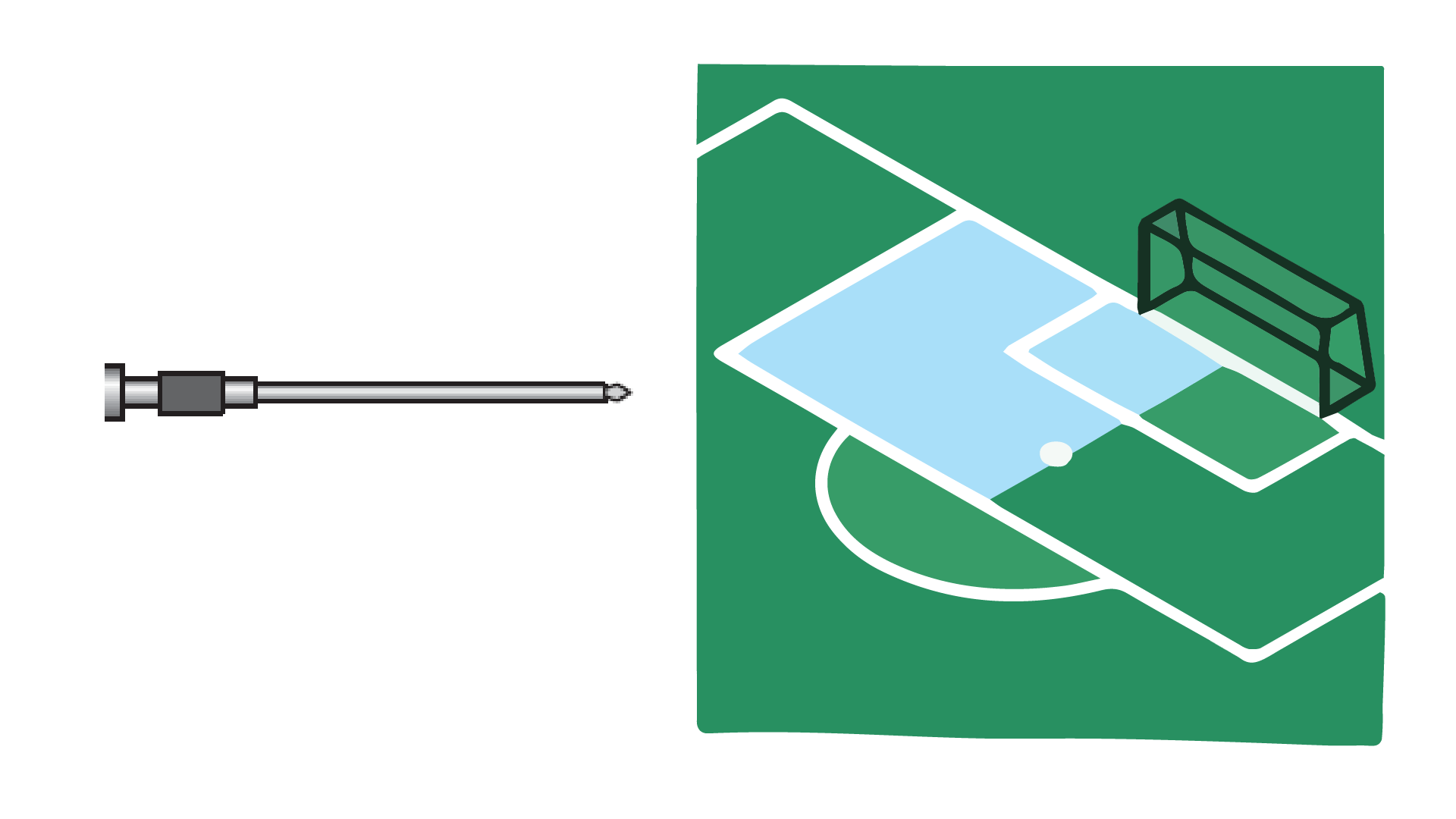

The same amount of water introduced at 40 bar will cover half the penalty field.

The same given amount of water introduced by a Cobra at 260 bar will cover the whole football pitch field.

Sources:

Försth, M & Möller, K. (2011). Absorption of heat radiation in liquid droplets. SP Technical Research Institute of Sweden.

Försth, M; Ochoterena, R & Lindström, J. (2012). Spray characterization of the cutting extinguisher. SP Technical Research Institute of Sweden.